Slide bearing machining process details:

First, raw material preparation The first step of slide bearing processing is to choose suitable raw materials, usually used steel materials, such as high carbon steel, low carbon steel and so on. In the material selection, need to consider the bearing load, friction, wear and other factors, choose the right material.

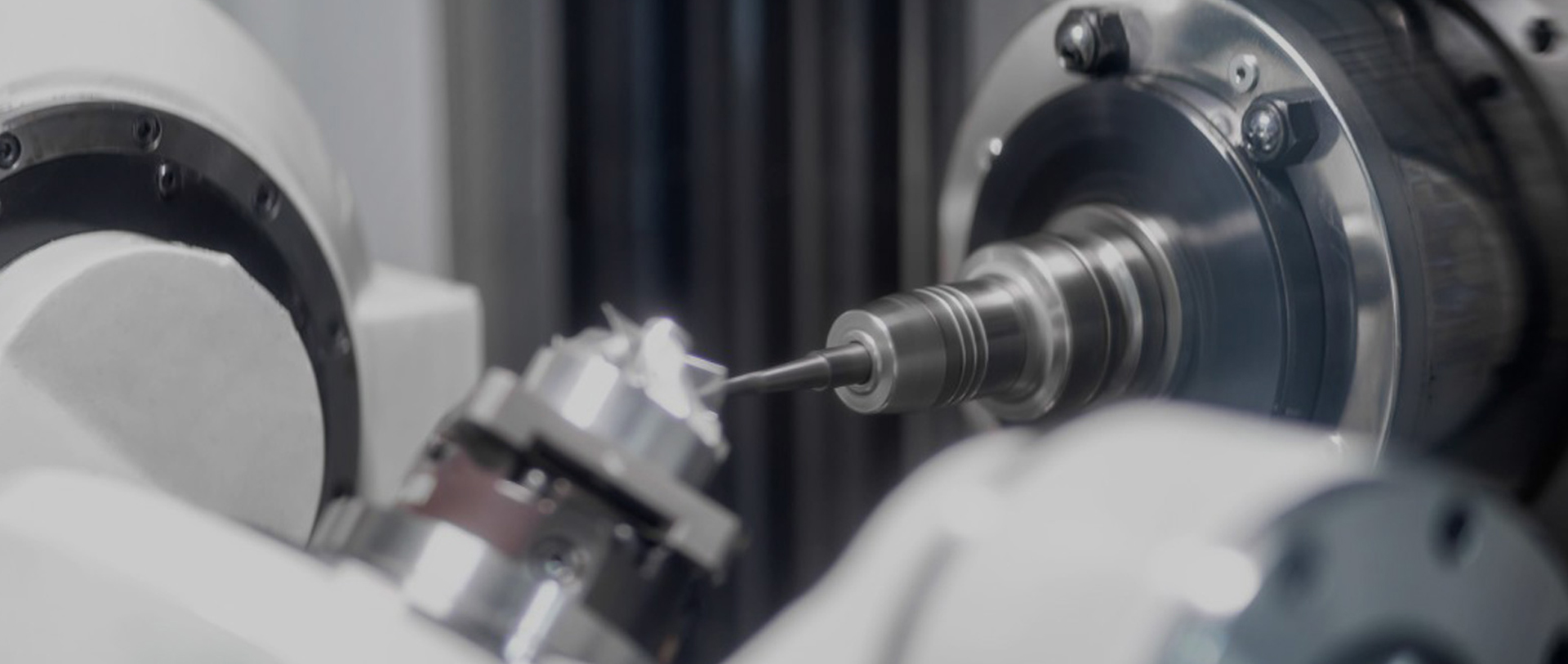

Second, turning processing Turning processing is one of the key steps in the production of plain bearings, the purpose is to process the round material into precise shape and size to meet the required quality standards. It is also one of the most basic machining process in bearing manufacturing. Turning operation requires fine machining equipment and technology to ensure machining accuracy and surface quality.

Third, the grinding process in the sliding bearing processing process, grinding processing is one of the necessary steps, the purpose is to have been processed on the surface of the bearing for subsequent processing, in order to ensure the machining accuracy under the premise of improving the surface quality. Commonly used grinding methods are plane grinding and ball grinding, need to repeat the process to achieve the required accuracy.

Fourth, copper plating coating in the processing of sliding bearings, need to be in the turning and grinding after the bearing surface for copper plating, this is to improve the wear resistance and corrosion resistance of the bearing. Copper layer thickness should be set according to the requirements of the bearing, usually tens of microns.

Fifth, playing oil holes, grooves in the use of bearings, the need for oil lubrication to reduce wear and friction, and can reduce the working temperature at high speed rotation. Therefore, in the production process of bearings need to build oil holes and grooves for lubricant filling and lubricant circulation.

Sixth, quality inspection, marking, packaging slide bearing processing is completed, need to carry out strict quality inspection, including dimensional accuracy, surface quality, copper layer thickness, oil holes grooves and other tests. After passing the test, then marking and packaging, so as to facilitate identification and management during transportation and storage.