First, careful selection of materials: to build a solid foundation for the first step in the production of linear bearings, focusing on the careful selection of materials. The use of high-quality cold-drawn steel, hot-rolled or cold-rolled steel strip, to ensure that the carbon content of the material is maintained at 0.15% to 0.25% of the ideal range, in order to adapt to the needs of different size bearings. In addition, the precise control of material hardness is key, too soft or too hard are not conducive to the long-term performance of the bearing.

Cold Extrusion Technology: The Art of Shaping The next process is cold extrusion molding, which requires precise cutting of the material to the appropriate length, followed by pickling and cleaning, cold heading operations, until the formation of the basic shape of the linear bearing. The core of this stage is to closely monitor the quality of the material to ensure that the process does not impair its intrinsic properties.

Third, heat treatment: strengthen the intrinsic quality of cold extrusion forming, heat treatment process immediately after the start, aimed at optimizing the microstructure of steel, enhance its comprehensive mechanical properties. The process covers tempering and quenching two major technologies, the former applies to high-carbon steel, balancing hardness and toughness; the latter for low-carbon steel, designed to enhance the hardness, the two complement each other, together for the bearings to create a solid “bone”.

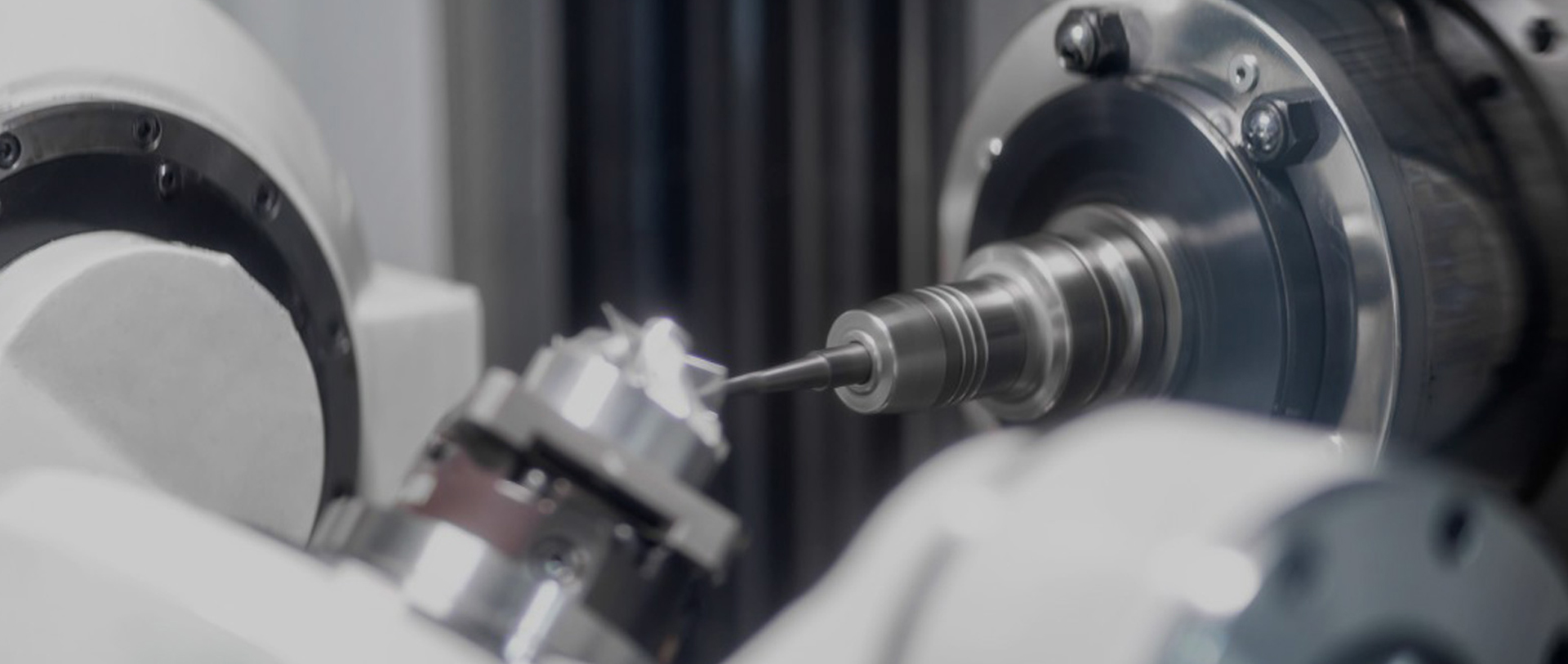

Fourth, precision trimming: details determine perfection through heat treatment bearings also need to go through a series of precision machining, such as turning, grinding and tooth surface treatment, each link has stringent requirements for precision, designed to ensure that the bearing's high precision and perfect roundness performance. This stage not only tests the precision of high-end equipment, but also relies heavily on the exquisite skills of technicians.

Fifth, precision assembly: the overall precision processing of the construction function is completed, entering the assembly stage. The use of locking devices, hammers and test fit plugs and other professional tools, follow strict procedures and norms, carefully assembled each piece of bearing, to ensure its functional integrity and stability and reliability.

Conclusion: Craftsmanship, the achievement of excellence bearing linear bearing production process, is a fusion of high-tech equipment and superb craftsmanship precision journey, each step is directly related to the final quality and service life of the product. This is not only a technology, but also a kind of art of the ultimate pursuit of details, reflecting the deep heritage of the modern manufacturing industry and the relentless pursuit.